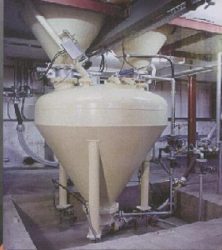

Pneumatic conveying by pressure vessel

Pressure vessel or dense phase Pneumatic conveying carries much larger quantities of product than other types of air transport.

The bulk product is emptied into a pressure vessel (e.g. 300 lt), into which compressed air is fed through an air compressor (e.g. at 2.5 – 3.0 bar).

Pneumatic conveying by pressure vessel is discontinuous, as once one batch of product is transported, there is dead time to refill the pressure vessel.

The loading of the system (ratio of kg of transported product to kg of air) is high (e.g. 40/1), which is why it is called dense phase pneumatical conveying.

Airlift by Pressure Vessel

Inside the tube, the product is transported in concentrated “plugs”, which limit its wear.

Ideal system for high yields (50 ton/h) and long distances (200 m). Needs an air compressor.