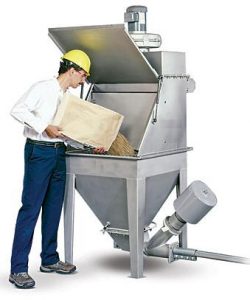

Bag tipping stations

Bag tipping stations (10 kg, 25 kg, or 50 kg) are defined by the term bag tipping stations.  The operator empties the sacks into a hopper with a lid. The height of the visor, where the operator rests the bag, should be close to 80 cm. Usually the operator, after temporarily fixing the bag, cuts a slit in the bag with his knife so that he starts emptying the product into the hopper.

The operator empties the sacks into a hopper with a lid. The height of the visor, where the operator rests the bag, should be close to 80 cm. Usually the operator, after temporarily fixing the bag, cuts a slit in the bag with his knife so that he starts emptying the product into the hopper.

There is a suction nozzle to guide the generated dust to a filter. There may also be plastic blinds, which will prevent dust from escaping. It is useful to have a min. level sensor, which alerts when the hopper is empty. At the outlet of the hopper can be placed a conveyor like an auger, rotary valve, air transport system, etc. It is useful to have a protection grid so that no foreign particles fall into the bag tipping station.