Belt Conveyors

Conveyor belts transport different raw materials without causing damage to them. On both ends, they have rolling drums, while along the length there are rollers – guides. We specialize in bulk product conveyor belts for industrial use. There are several categories of belt conveyors.

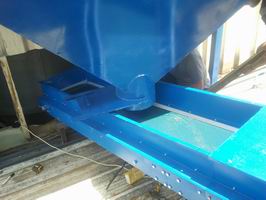

Flat conveyor belts

Flat conveyor belts usually rest on a flat sheet metal either horizontal or inclined. Rollers only exist under the belt on the return journey. Flat conveyor belts can transport all coarse bulk products such as feed pellets, croquettes, etc. which are fragile.

They are also applied in the field of packaging for transporting a packaged product, such as a 25-kg bag.

Depending on the material of the belt, conveyor belts are divided into other categories.

Smooth surface conveyor belts

The strap material is smooth plastic. The conveyor belt cannot be inclined more than 15°, otherwise the product will slide back.

Conveyor belts with anti-slip surface

The material of the belt is anti-slip “rough” plastic with grooves, which allow the conveyor belt to incline up to 30°, otherwise, the product will slide back.

Conveyor belts with cleats

The material of the strap is plastic and has pockets or cleats each 500mm, which look like buckets or compartments. It also has profiles on both sides along the length. The conveyor belt of this type can incline up to 60° without the product sliding back.

Perforated belt conveyors

The material of the belt is perforated metal mesh or plastic perforated mesh that allows the conveyor belt to drain or spill liquids down, or to pass drying or cooling air through it to dry the conveyed material.