Batch mixers (discontinuous)

Batch mixers of a specific capacity mix each time the specific batch, e.g. 1000 kg in the specific mixing time, e.g. 3 min.

Dead times of mixer filling and mixer emptying should be counted in a full batch cycle.

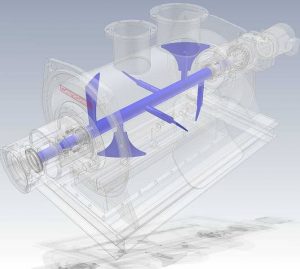

There is usually a (horizontal) rotating shaft with either 2 rows of counter-current stirring knives called ribbons, or paddles, depending on the requirements of the mixture.

Other types of batch mixers are:

- mixers with 2 shafts,

- vertical conical mixers with planetary rotation of the rotating shaft,

- shaftless mixers with rotating drum movement, etc.

At the bottom of the mixer, there is an emptying valve, usually driven by a pneumatic actuator or cylinder. Important issues of batch mixers are a reliable and dust-tight outlet valve, a quick emptying time of the mixer, and full emptying of the mixed product.

The mixing time and the degree of homogeneity of the mixture are related to the cost and quality of each mixer.

To increase the efficiency of a mixing plant, it is useful to foresee a weighing hopper over the mixer and a buffer of similar capacity under the mixer.

.

Plough-share mixers

They are batch mixers, which on their shaft have reins, shaped like the plow that plows the earth. They are often used for abrasive products, where the ribbon mixer would soon wear out.