Magnetic grids

Magnetic grids are used to separate

ferrous impurities contained in granules, powders and liquids. Grids are placed inside pipes or funnels. It is easy to install and does not need any special maintenance procedure, just a manual cleaning from time to time. They are made entirely of stainless steel AISI 304 and watertight sealing, with circular, square, parallelogram or any other shape. Magnetic field: – Standard with ferrite (Fe) – High efficiency with neodymium (Nd)

Magnetic bars

The magnetic bar is made of stainless steel or brass tube.

It is used in the processing of granular materials, powder, wood, etc. and has been studied to separate the ferrous impurities contained in them. Entirely made of stainless steel AISI 304, when used mainly in the food industry. It can be supported by a screw thread. The only maintenance required is manual cleaning. Magnetic field: – Standard with ferrite (Fe) – High performance with neodymium (Nd)

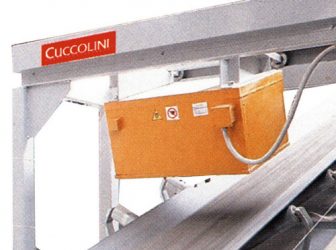

Magnetic bars in a box

SPECIFICATIONS:

• Magnetic strength: 16,000 Gauss (in a closed space)

• Weight: 10 kg

• Number of magnetic bars: No.5

CONSTRUCTION FEATURES:

• In a removable box

• Entirely made of AISI 304 stainless steel

• Permanent magnetic bars, in neodymium

• Fast closing

• Manual cleaning

APPLICATIONS:

• For dry powder or granular materials

• After a breaker

• After conveyor belt

ADVANTAGES:

• High performance

• Easy installation

• Maintenance free

Magnetic zig-zag traps

Magnetic traps are used to remove ferrous parts from granular materials, thus guaranteeing the quality of the product as well as the safety of each machine. The magnetic traps are placed inside the tube and on the opening doors. The ferrous parts are attracted and held onto the poles of the permanent magnet. They can be removed after stopping the product flow by opening the door, the large dimensions of which allow manual cleaning operations. The magnetic traps are made entirely of stainless steel.

Magnetic plates

Magnetic plates are used to separate the ferrous parts. When a very high separation is required, they can be combined with a magnetic cylinder. Magnetic plates are the simplest and cheapest equipment to protect crushing and milling plants. The magnetic plate, which is protected by a waterproof stainless steel cover, allows the use of these plates in any environmental condition.