Material Handling Fans – Blowers – Ventilators

Ventilator

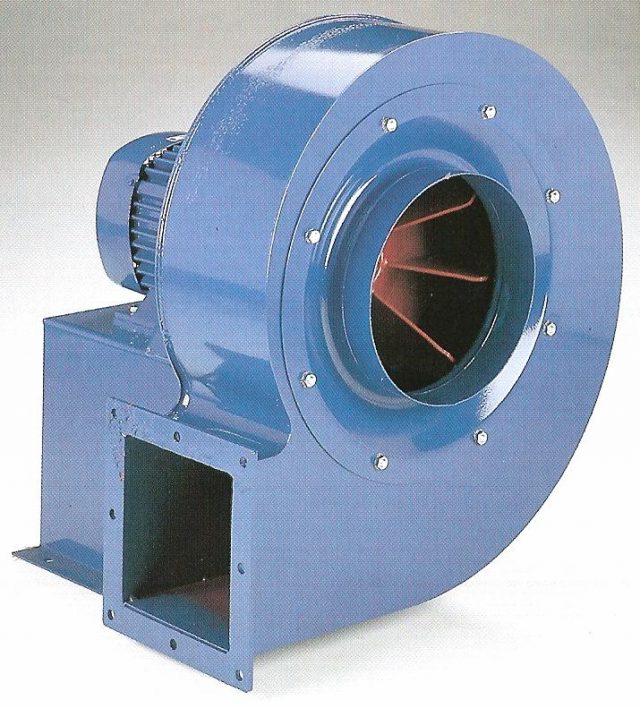

FANS (centrifugal fans)

FAN – GENERAL DESCRIPTION

Centrifugal fans (centrifugal fans) suck in / propel air or a mixture of air and product (dust) and carry out the dedusting or otherwise removal of dusty / polluted air. There are different categories of ventilators.

FANS / CATEGORIES / TYPES

PRODUCT TRANSPORT FANS (material handling fans).

Aviation fan

Centrifugal fans of this type are located before the filter and transport together with the air and the product, such as sawdust, sawdust, broken corn from the mill, broken plastic flakes, fibers, paper scraps, light dusts, etc. Their propeller has backward inclined blades, so it is self-cleaning. The motor can be connected directly and then gives 2880 rpm. The fan JK25D – 4.0kW with suction inlet Φ250mm has a delivery of 4’000m3/h at a vacuum of 1800Pa. Also the motor can be connected in parallel with pulleys. The fan JK40K – 15.0kW at 2600 rpm with suction inlet Φ400mm has a delivery of 9’000m3/h at a vacuum of 3000Pa

LOW PRESSURE clean air fans.

Centrifugal fans of this type are located after the filter and carry clean air. Their propeller has backward inclined blades, so it is self-cleaning. It is designed to give maximum air flow with the least possible energy consumption. The motor can be connected directly and then gives 2900 rpm. The fan JK40MTD – 11.0kW with suction inlet Φ400mm has a delivery of 7’000m3/h at a vacuum of 3300Pa. Also the motor can be connected in parallel with pulleys. The fan JK50MT – 22.0kW at 2150 rpm with suction inlet Φ500mm has a delivery of 10’000m3/h at a vacuum of 3850Pa.

MEDIUM PRESSURE AIR TRANSPORT FAN (BLOWER).

Airlift Blower

Centrifugal fans of this type are propulsion and located at the beginning of the line or suction and located at the end of the line after the filter and clean air passes through them. They are used for the air transport of products such as plastic pellets, grains, granular materials in a network of pipes with Φ160mm. Their propeller has backward inclined blades, so it is self-cleaning. The Blower TRL55 – 4.0kW with suction inlet Φ160mm has a delivery of 1’800m3/h at a vacuum of 6500Pa at 2850 rpm. The Blower TRL100 – 7.5kW with suction inlet Φ160mm has a delivery of 1’800m3/h at a vacuum of 9500Pa at 3650 rpm.

HIGH PRESSURE SIDE CHANNEL BLOWER.

Side channel blowers are propulsion and are located at the beginning of the line or suction and are located at the end of the line after the filter and clean air passes through them. They are used for the air transport of products such as plastic pellets, grains, granular materials in a network of pipes usually with Φ50-Φ100mm. The Side Channel Blower MA75 – 7.5kW with suction inlet Φ80mm has a delivery of 395m3/h at a vacuum of 25’000Pa (250mbar) at 2900 rpm.

HIGH PRESSURE ROOTS BLOWER.

Roots Blower

Roots Blowers are propulsion and located at the beginning of the line or suction and located at the end of the line after the filter and clean air passes through them. They are used for the air transport of products such as plastic pellets, grains, granular materials in a network of pipes usually with Φ50-Φ100mm. The Roots Blower RO75 – 7.5kW with suction inlet Φ90mm has a delivery of 374m3/h at a vacuum of 40’000Pa (400mbar) at 3600 rpm.