Rotating magnets & magnetic separators

In many cases, raw materials have small metal particles, screws, burrs or objects that damage the production and must therefore be removed. Magnets or magnetic separators should be installed at the beginning immediately after receipt, usually in free flow.

Drum magnets in a box

The magnetic sorting machines are supplied with a stainless steel structure,

where the granular and fine materials are transferred to a separation drum. Once the material has the proper separation, it flows to two different outlets.

The rotation of the drum results from the motor located outside the box. Regarding the separation of fine-grained materials, the use of sorting machines with neodymium magnets is recommended. They find application in milling and ceramic industries.

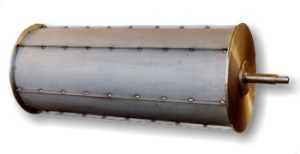

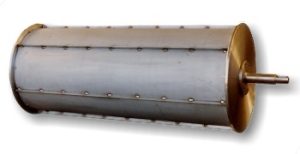

Magnetic drums

Magnetic drums consist of a 180° magnetic core. This core is contained within a rotating non-magnetic casing “shroud”.

drum magnets

Permanent magnet drums allow continuous and automatic separation of ferrous objects. They are placed outside the conveying medium, whether it is a belt, skid, or vibrating scoop. The adjustable rotation magnetic core is positioned so that the rotating cover drags the materials along, drawing the ferrous objects past the magnetic field. The magnetic drum is for this reason the most versatile separator since it can catch both thick and fine ferrous materials that require very thin and uniform layers. If very strong separation is required, it is better to use more than one drum in the fall. Magnetic field: – Standard with ferrite (Fe) – High efficiency with neodymium (Nd), on request

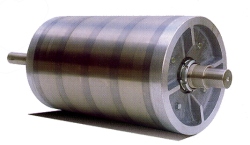

Magnetic rollers (magnetic rollers)

Magnetic rollers are placed at the front of the conveyor belts to separate and reject small and medium-sized ferrous metal particles.

The particles are attracted by the magnetic field produced by permanent magnets, which are located inside the cylinder. The cylinder is made of stainless steel AISI 304 Magnetic field: – Standard with ferrite (Fe) – High efficiency with neodymium (Nd), on request

Tape magnets

Overbelt magnetic separator belts are used to separate ferrous objects, mixed with non-magnetic materials transported by conveyor belts.

Magnetic field:

- Standard with ironite (Fe)

- High efficiency with neodymium (Nd)

Motorization:

- With electric reduction gear in the basic equipment

- Optionally with hydraulic motor.

Advantages:

- Zero energy consumption

- Permanent magnetic field

- Guaranteed continuous operation since the magnetic field cannot be interrupted

- Minimal need for maintenance, only for the mechanical parts

Application to:

- Aggregate crushing units

- Solid waste recycling

- Recycling of wood, plastic and other materials

Article on magnetic separators:

https://www.processindustryinformer.com/50-shades-of-magnetic-separators/